Why planned maintenance and other good info from two EMR techs

In an industry where there is never enough time to do it all, it is easy to put off the essential task that is commercial kitchen equipment planned maintenance (PM). PM work allows minor issues to be resolved before developing into major breakdowns. “It doesn’t have to be the most elaborate thing to be comprehensive and worthwhile,” Dave Fitch says. “At least once a year a professional should look over the equipment from top to bottom to uncover any hidden, budding issues, most of which can be handled quickly.”

planned maintenance (PM). PM work allows minor issues to be resolved before developing into major breakdowns. “It doesn’t have to be the most elaborate thing to be comprehensive and worthwhile,” Dave Fitch says. “At least once a year a professional should look over the equipment from top to bottom to uncover any hidden, budding issues, most of which can be handled quickly.”

Whether you have 20 pieces of equipment or 200, a PM program is in your best interest. Find out why with Dave Fitch and fellow tech, Matt Gingrich’s intel below.

Fewer Emergency Calls

Scheduling a PM helps prevent sudden, unexpected equipment failure that is bound to cause chaos in a commercial kitchen. Dave asks “Don’t you want to feel reassured that you’re doing what you can to prevent equipment failure and the need for emergency repair calls during high volume time periods?” The answer is a resounding YES. When you know your equipment is in optimal condition, you can focus your attention on other aspects of your business, spending less time worrying and less money over all.

Less Down-time

When smaller problems are solved while the tech is on site for PM work, it can avoid bigger issues that cause major equipment breakdowns. These issues are not only expensive but can cause a complete shut-down of the kitchen if the problem takes days to fix. Matt makes an important point that “machine down-time is inevitable when routine maintenance is being performed, and if you have the opportunity to schedule the work at a more convenient time (i.e., after hours) you can minimize the disruption to your operation.”

Extend Equipment Lifespan

Commercial kitchen equipment is an investment. After such an expensive purchase, dumping more money into upkeep is the last thing an operator cares to do. However, keeping it in good condition allows it to run longer, lowering costs. Dave mentions that “equipment will eventually wear out at some point. The goal of a PM program is to keep your equipment running efficiently, for as long as possible.”

Maintain Food Quality

The number one reason people go to restaurants is for delicious food and drink. Matt’s concern for operators is that “if kitchen equipment is not properly maintained, it affects the overall quality of the food served.” If a refrigerator is not functioning properly, food can spoil. If an oven is not reaching the appropriate temperature, food can be undercooked. The last thing business owners want is a bad reputation. By simply having a PM program, they can avoid these issues and be sure they are serving the best quality of food that exceeds standards and has folks coming back for more.

Saves You Money

“For restaurant operators, cutting costs is a huge priority,” Matt adds. “PMs can help save money in the long run. And with many operators reeling from the pandemic, keeping costs low matters.” Restaurants can save 15-30% annually on repair & maintenance, if equipment is correctly maintained with the proper PM program in place.

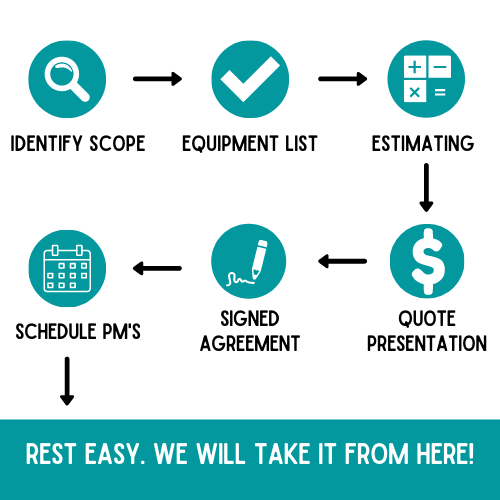

There’s a common theme throughout these planned maintenance benefits – AVOID SPENDING MORE MONEY. Work proactively with a professional service company to control unnecessary repair costs for your equipment. Depending on the size and scope of your kitchen, approval processes, and budgeting, getting set up with a PM agreement takes approximately 2 weeks start to finish. From there, you can rest knowing a pro will be onsite inspecting your equipment regularly so operators can focus elsewhere.